Accutron information

History

It has been said by others that the Accutron watch was developed by the Bulova Watch Company as a response to a perceived requirement by the American Army for a better time standard. I don't know whether that is true or not.

Bulova Technical Documentation states quite clearly that the watch was developed entirely as a consumer item, with no funding from any outside source. Still, it might be fair enough to imagine that the potential military applications hadn't gone unnoticed by Bulova management. The CEO of Bulova at the time was Omar Bradley, 5 Star General, US Army, Retired. All research undertaken was performed by Bulova engineers in their own labs.

Bulova Accutron

Main

Service Center

Although the tuning fork concept had been had been previously demonstrated in clocks, they were never mass produced, let alone miniaturized to watch-size. Work began on the development of a Tuning Fork watch in 1953 by the engineer Max Hetzel.

The first protype watches were produced in Switzerland in 1955. In 1959, Max Hetzel and William Bennett developed the Bulova Accutron at the Bulova Headquarters in New York, based on Hetzel's previous research in Switzerland.

The first Bulova Accutrons were offered for sale to the public in November 1960. These were the Accutron Model 214.

Production of tuning fork Accutrons ceased in 1977, with Bulova directing their efforts to producing quartz watches. The name "Accutron" is still used by Bulova on some of their quartz watches. These watches bear no relationship at all to Tuning Fork watches.

Technical

Information

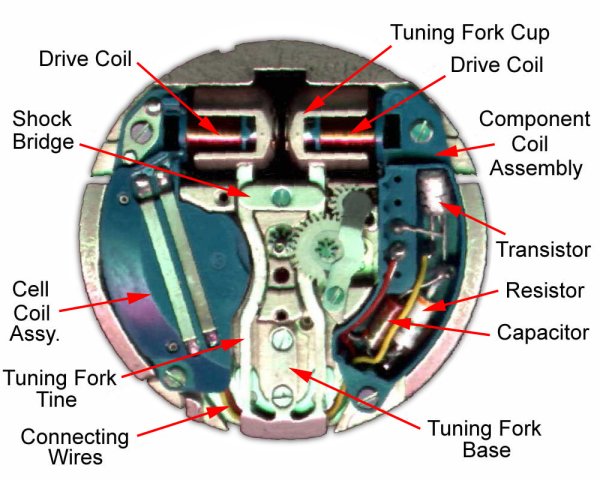

Like conventional watches, Bulova Accutrons have a train of gear wheels to drive the hands. And that is basically where the similarity ends. In an Accutron, there are two areas of special interest. One is the Electronic Circuitry and the other is the Index Mechanism .

The Electronics

While it is relatively simple, it is neverthless interesting how the electronics driving the Accutron works. The electronic circuit combined with the tuning fork forms a simple oscillator. Each of the ends of the tuning fork has a little magnet on it. The fork provides the resonant or tuned part of the circuit. Both of these magnets are surrounded by a coil of very fine wire attached to the body of the watch.

Power from the battery flows through the transistor, and then through both of the driving coils. One of the coils (the one which is attached to the plate holding the transistor and its components) also has a secondary coil built into it. When the fork springs one way, this secondary coil provides a feedback voltage which cause the transistor to almost stop the flow of current in the driving coils, and stop driving the fork. When the fork springs back the other way, this feedback coil generates a "reverse" voltage, which causes the transistor to allow current to flow in the driving coils again. The fluctuating current in the driving coils produces a varying magnetic field, which alternately attracts and repels the tuning fork magnets. Thus it keeps on vibrating. The system is self-regulating. If the watch receives a jolt which adds to the fork vibration, the circuit automatically reduces power to the fork until it reaches the normal amplitude of vibration. The reverse is also true.

One of the more interesting features of the electronics are the coils themselves. Each Accutron coil has 8,100 turns of insulated copper wire of 0.015mm diameter (or about 1/2000th of an inch). That equates to about 80 meters (or nearly 90 yards) per coil. The wire is about one-third the thickness of a human hair.

The Index Mechanism

This mechanism provides the means for converting the vibrations of the tuning fork into rotary motion. Even today, it is considered a truly remarkable engineering accomplishment. Though the dimensions of the working parts are incredibly small, the operation of the index mechanism is elegantly simple, and its robustness and reliability legendary. Neverthless, it is very delicate and requires special handling techniques during servicing and adjustment. The index wheel can be destroyed by simply touching it on its rim. It must be handled by its pinion only.

It consist of two very fine flat springs (or "fingers"), each with a small ruby jewel cemented with epoxy onto one end. One of the springs (the pawl finger) is attached to the body of the watch by a small movable carrier and post. The other (the index finger) is attached to a post mounted on one arm of the tuning fork. The jewels of each finger rest on a special ratchet wheel (the index wheel) which has very small triangular shaped teeth. These teeth are so small, they cannot be seen without the aid of a microscope.The positions of the index and pawl jewels relative to each other is adjusted by moving the pawl jewel carrier. Correct adjustment is necessary to allow for variations in fork amplitude during the life of the battery. This is known as "phasing" the index mechanism, and requires good watchmaking skills, experience on Accutrons, and a good understanding of the operation of the index mechanism to be carried out correctly.

In operation, when the fork moves towards the index wheel, the index jewel pushes the wheel around slightly more than one tooth. The wheel is then locked in place by the pawl jewel, so when the fork and index jewel moves back away, the index wheel stays stationary. This occurs once for every vibration of the fork, or 360 times a second for a 214 or 218 Accutron movement.

The index wheel of a 218 movement is 2.40mm (0.095") in diameter and has 320 teeth, each of which is about 0.01mm high (0.0004") and 0.02mm (0.0008") wide. The index and pawl jewels are perfect little square blocks of synthetic ruby, 0.18mm (0.007") square and 0.06mm (0.002) thick. How these parts were manufactured has remained a closely-guarded secret.

The illustration below depicts a Accutron Model 214 dated 1960

Croydon

Service Centre, Bulova Vintage, PO Box 247, Westerham, TN16 9FA

Tel: + 44 (0)20 8680 1572

Fax: + 44 (0)20 8680 1572